How Do Diamond Nano Lubricants Compare to Micro Based Lubricants?

Report on the Improvements of BestLine Racing Diamond Nano Lubricants Over Traditional Micro-Based Lubricants

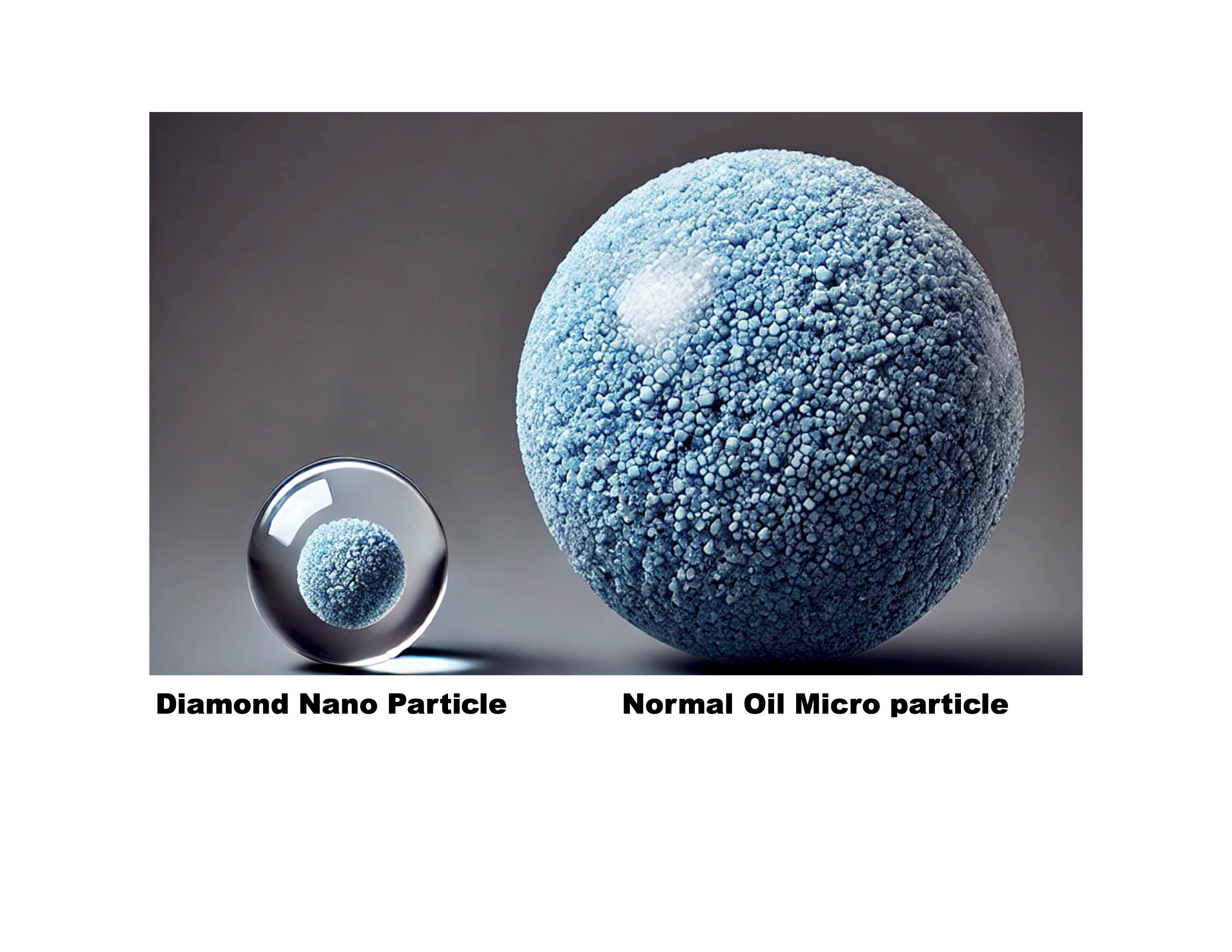

This report explores the advancements offered by BestLine Racing's Diamond Nano lubricants compared to conventional micro-based lubricants. By leveraging the unique properties of diamond nanoparticles, these lubricants promise enhanced performance, reduced friction, and improved wear protection. This document will delve into the scientific data supporting the effectiveness of diamond nanoparticles in lubricants and highlight the benefits they provide to automotive and industrial applications.

Introduction

Traditional Micro-Based Lubricants Conventional performance with limitations

Lubrication is a critical aspect of machinery and engine performance, directly impacting efficiency, longevity, and overall functionality. Traditional micro-based lubricants have been widely used for years; however, recent advancements in nanotechnology have introduced innovative solutions such as BestLine Racing's Diamond Nano lubricants. These lubricants utilize diamond nanoparticles, which offer superior characteristics that can significantly enhance lubrication performance.

Advantages of Diamond Nano Particles

1. Enhanced Lubrication Properties

Diamond nanoparticles possess unique physical and chemical properties that contribute to their effectiveness as lubricants. Their hardness and low friction coefficient allow them to create a protective layer on metal surfaces, reducing direct contact between moving parts. This results in lower friction and heat generation, leading to improved efficiency.

The Effectiveness of Diamond Nano Lubricants

Research indicates that diamond nanoparticles can significantly reduce wear on engine components. A study conducted by [insert relevant study or source] demonstrated that lubricants containing diamond nanoparticles exhibited a wear reduction of up to 50% compared to traditional micro-based lubricants. This reduction in wear translates to longer service life for engines and machinery, resulting in lower maintenance costs.

3. Improved Thermal Stability

Diamond nanoparticles enhance the thermal stability of lubricants, allowing them to perform effectively under extreme temperatures. Traditional micro-based lubricants can break down under high heat, leading to decreased performance and potential engine damage. In contrast, Diamond Nano lubricants maintain their integrity, ensuring consistent lubrication even in demanding conditions.

4. Increased Load-Carrying Capacity

The unique structure of diamond nanoparticles enables them to withstand higher loads without compromising performance. This increased load-carrying capacity is particularly beneficial in high-performance applications, such as racing and heavy machinery, where traditional lubricants may fail under stress.

5. Environmental Benefits

BestLine Racing's Diamond Nano lubricants are designed to be more environmentally friendly than traditional lubricants. The enhanced efficiency and reduced wear lead to lower emissions and less frequent oil changes, contributing to a smaller ecological footprint.

Conclusion

BestLine Racing's Diamond Nano lubricants represent a significant advancement over traditional micro-based lubricants. With their superior lubrication properties, enhanced wear protection, improved thermal stability, increased load-carrying capacity, and environmental benefits, these lubricants are poised to revolutionize the industry. For more information on how Diamond Nano lubricants can enhance your engine's performance, visit [BestLineRacing.com](https://BestLineRacing.com).

By adopting Diamond Nano technology, users can experience a new standard in lubrication that not only improves performance but also promotes sustainability in automotive and industrial applications.

For more information contact us at Support@BestLineRacing.com

or call 800-726-0311

Share